Mastering the Art of Precision Metalworking: Techniques, Tools, and Theory

What you will learn

Gain a comprehensive understanding of the machining process and its applications in the metalworking industry.

Explore the various types of machines used in the machining process, and learn how to choose the right machine for a given task.

Discover the critical role of machining and part geometry in the machining process, including an in-depth look at rotational and non-rotational elements.

Perfect your drilling skills, including cutting conditions in drilling, and learn how to drill with precision and efficiency.

Master the art of turning, including cutting and turning conditions, and learn how to apply these techniques to produce precise and accurate cuts.

Enhance your drilling skills, including cutting and drilling conditions, and learn how to drill with precision and efficiency.

Get hands-on experience with the boring process, including horizontal and vertical boring techniques, and learn how to achieve efficient and accurate results.

Develop your milling skills, including cutting conditions in milling, and learn how to mill with precision and efficiency.

Perfect your drilling skills, including cutting conditions in drilling, and learn how to drill with precision and efficiency.

Description

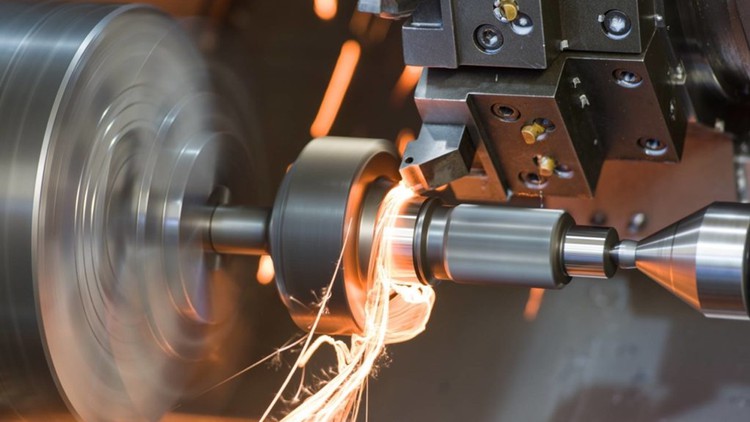

“Unlock Your Potential in Metal Machining with the Ultimate Comprehensive Course: ‘Fundamentals of Advanced Metal Machining Techniques'”

Are you looking to advance your metalworking skills and stay ahead of the competition in the industry? Then look no further, as this comprehensive and engaging course, “Fundamentals of Advanced Metal Machining Techniques,” is perfect for you. Led by a highly experienced instructor with a PhD degree in the field, this course provides a wealth of knowledge and hands-on experience in the art of metal machining.

The course covers a wide range of topics, from the introduction to machining processes, to the different types of machines used in the machining process, and the advantages and disadvantages of metal machining. You will learn about the crucial role that machining and part geometry play in the process, and explore cutting and turning conditions in turning, drilling, boring, and milling processes. You will also gain hands-on experience with each technique, allowing you to apply your knowledge in real-world scenarios.

By the end of this course, you will have a comprehensive understanding of the metal machining process and the skills you need to succeed in the field. This is a unique opportunity to take your metalworking skills to the next level and stand out in the highly competitive world of metalworking.

Don’t miss out on this incredible opportunity to invest in your future and become a master in metal machining. Enroll now and join the thousands of students who have already transformed their careers with this comprehensive course. Get ready to take your metal machining skills to new heights and unlock your full potential!

Content