You will get knowledge on how to process yoghurt , maintain its quality, expand market and maintain customers confidence

What you will learn

Best practices observed when processing quality yoghurt that meets market standard availed which assures the public safety and health for consumers in general

What do we mean by temperature time combination, indirect heating ,agitation, holding time, drastic cooling, incubation, breaking of curd in yoghurt processing.

15 simple things you should know when you are in the production of quality yoghurt with an aim of delivering a safe product which is of the market standard set

How to segregate good quality milk from bad quality milk using the five senses i.e. check acidity level, check for any adulteration (added water) any foul smell

Reasons for agitating milk while heating in yoghurt processing, and why homogenization, right incubation temperatures ,right cultures and colors are paramount .

Description

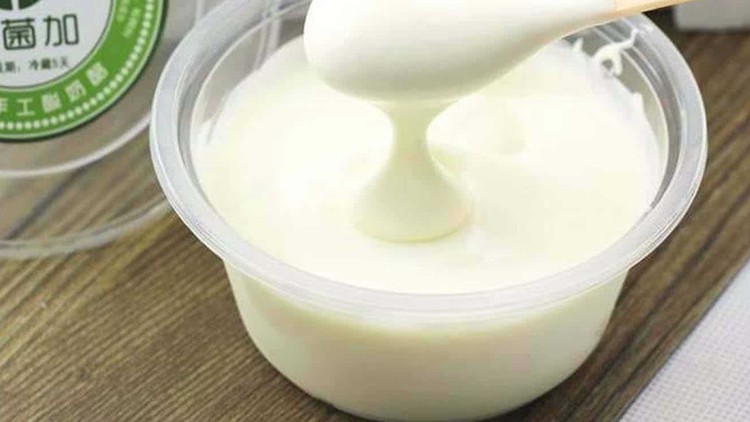

Yoghurt processing is a simple way of fermenting well pasteurized milk .The pasteurized milk is cultured with the Yoghurt fermenting micro-organisms and incubated for the given period.

This course needs a person who can understand and willing to follow instructions on how to employ the technology.

Yoghurt is a nutritious milk product profitable to people of all ages. Its a complete food rich in carbohydrates, proteins, fats, vitamins, minerals, fiber and water. It is important that everyone consumes these seven nutrients on a daily basis to help them build their bodies and maintain their health.

Its demand is high therefore quality is key as we engage in the processing. We have the responsibility of ensuring safety of the public as we also meet the customers expectations; as well as our product being to the standards set by the governments. Quality product is key for any growing market space and also maintaining the same.

Processing yoghurt product can be done with or without machines. Its okay once the technology required is rightly captured and followed. For this case; the processing is easy and can be done in a home set-up.

Its required that the personnel handling milk should be medically certified ,the environment should be clean with fresh air and without any foul smells, the animal being milked should be healthy, the equipment should be recommended for milk handling , the detergents should be of light lather and mild smell so as not to introduce any form of contamination.

Milk should not have any traces of veterinary drugs, off flavor e.g. from feeds, and taints

Adulteration by water addition in milk is a prohibited culture though this is done by unfaithful traders for a the purpose of getting much from their investment.

Follow carefully the procedures for milk pasteurization, inoculation , incubation ,cooling and finaling evaluation of the product.

Milk handled for the purpose of processing should be hygienically done that includes;- during production, transportation, processing and storage to avoid contamination. Same to the finished products.

Once poor quality raw material is processed the final product will also be poor. Garbage in garbage out.

Note:

To maintain standard of the product; – Sample testing of the output against specifications is paramount in maintaining the quality required .

How to segregate good quality milk from poor quality

Separation of milk depending on its quality is done by testing the milk before reception

These tests includes;

a. Organoleptic test

b.Alcohol test

c.Phosphatase test

d.Lactometer test

e.Sediment test

f.Clot on boiling test

These are tests which are quick to perform and give instant results

Organoleptic

In this test whereby a tester uses the five senses to do a judgement on the milk sample to check if its fit for the intended use.

Check for normal smell, colour, and consistency .If it does not comply its segregated or separated.

Alcohol test

This test is for checking for acidity level.

Though milk has a natural acidity there is a limit required and the excess of it renders the milk not to be fit for any further processing. Acidity increases due to presence of mastitis bacteria, developed acidity or colostrum milk ( colostrum has high amounts of proteins which are unstable when heated)

Procedure for alcohol test

Take small same amounts e.g. 2ml of milk and ethanol; Ratio 1:1 (Type of alcohol diluted to about 70 percent concentration) then mix

If the milk acidity is higher than expected; a precipitation is noted or clots.

If the acidity is normal no changes will be noted.

Phosphatase test

Alkaline Phosphatase is an enzyme which is naturally present in milk, but is destroyed at a temperature just near to the pasteurization temperature. Alkaline Phosphatase test is used to indicate whether milk has been adequately pasteurized or whether it has been contaminated with raw milk after pasteurization.

Procedure

In the sample picked for testing deep the testing strip.

A colour change is immediately realized if the milk is unpasteurized of re-contaminated with raw milk from blue to green.

No changes occurs when the milk is adequately pasteurized

For milk testing, lactometer is dipped in milk which we are testing. In lactometer, the point up to which it sinks in the pure milk is marked after that put in water and marked at the point up to which it sinks in water. It sinks less in milk than water because as we know milk is denser than water

If milk fat (cream) is added to milk, the density becomes lower. The equipment used to determine milk density is called a lactometer

HOW TO CHECK WATER ADULTERATION IN MILK BY USING LACTOMETER

Milk adulteration and the knowledge of the tests is necessary. The nutritional value of milk to human health needs no introduction. At the same time it is alarming that many vendors adulterating it with water, detergents, caustic soda, starch, formalin, urea, ammonium sulphate, sodium carbonate which have harmful effect on the human health. The greed for money has pushed them to the extent of producing synthetic milk which has no nutritional content. “Adulteration” is a legal term meaning that a milk product fails to meet federal or state standards. Adulteration is an addition of another substance to milk in order to increase the quantity of the milk in raw form or prepared form, which may result in the loss of actual quality of milk. Milk adulterated is mainly done for financial gain but it can also be adulterated due to unhygienic conditions such as processing, packaging, transportation, distribution etc. Water is the most common adulterant used which decreases nutritional value of milk and lowers the quality of milk.

A lactometer measures the density of milk. It tells the user how much water is in the milk that is being sampled. This is an instrument used to determine the richness of milk.

Lactometer : Measure the amount of water in the milk. A Lactometer is used to find out the amount of water in the milk. It works on the principle of specific gravity of milk. It consists of a Test-Tube and a Meter Bulb.

Using this instrument is very simple.

Put some milk in the test-tube.

Dip the meter bulb in it, the bulb going in first. You will notice that the meter bulb floats. The reading on the meter indicates how pure/impure your milk is.

The deeper the bulb sinks, the more dilute/impure the milk.

If the reading is at the red mark, it shows that the milk is rich and pure.

Milk is one of the most important ingredients for children’s overall development, it is essential for adult health as well.

Milk is also widely used in food item like desserts, baking, tea and coffee etc.

The most common reason for milk adulteration is the difference between demand and supply of milk. In order to meet the demand, the suppliers usually adulterate the milk and increase the quantity.

The adulterants like glucose add to the thickness and viscosity of the milk while starch prevents curdling of milk.

Due to lack of hygiene in milk handling and packaging, detergents (used during cleaning operations) are not washed properly and find their way into the milk. Other contaminants like urea, starch, glucose, formalin are used as adulterants. These adulterants are used to increase the thickness and viscosity of the milk as well as to preserve it for a longer period.

Water turned out to be the most common adulterant in milk. It reduces the nutritional value of milk. If contaminated (with pesticides, heavy metals), water poses a health risk to consumers

Sediment test

This is a test to check the amount of physical dirt in milk(sediments)

A clothing or sieve with fine openings is used to pass the milk through .The amount of dirt that will remain on top will determine the level of dirt that was in the milk hence its acceptability.

Clot on boiling test

This test also tests for increased acidity in milk

Procedure

Heat a small sample and if the acidity is low the milk ample will boil. If the acidity is high there will be noted a precipitation or clots.

Content