What you will learn

Gas Turbines

Steam Turbines

Turbo Expander

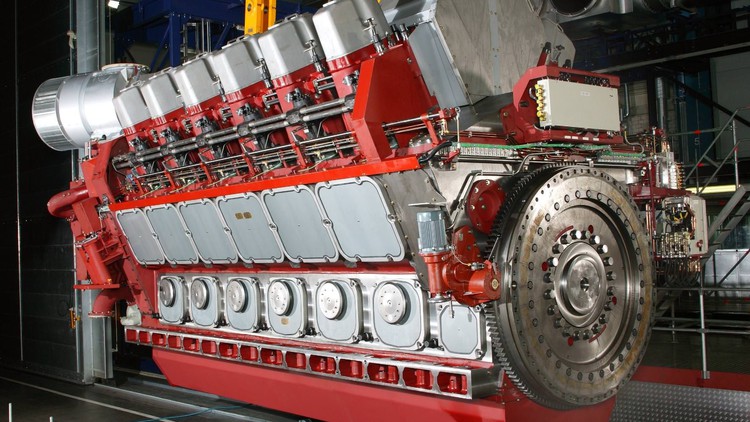

Gas Engines and Diesel Engines

Organic Rankine cycle

Description

Course goals:

-

To have an overview of all kinds of rotating equipment and their applications.

-

A complete understanding of construction details, functioning, and performance of pumps/compressors for successful plant operation

-

To know and study the different types of pumps/compressors, centrifugal, screw, and reciprocating. Their mechanical parts and hydrodynamic performance.

-

To know how to select and specify the type and model of pumps for a specific service according to international standards with CAPEX and OPEX optimization.

-

To Understand pump working principles for the successful operation of your plant and piping systems.

-

To learn how to read and interpret your pump compressor curves and system curves

-

To Optimize the operation efficiency of your pumping systems.

-

To Understand centrifugal pumps/compressors’ construction details (impeller, volute, shaft, bearings, packing, mechanical seals, etc.

-

Learn How to read and fill pumps datasheets, e.g. centrifugal, diaphragm, reciprocating, screw…etc.

-

To learn how to survey the market and identify market lead manufactures and their facilities worldwide.

-

To learn How to successfully witness the equipment testing and approve test results.

-

To discuss and clarify some installation and start-up activities’ important aspects according to international standards.

-

To know and select the different types of engines, power limitations, and applications.

Full Course contents:

1-Rotating equipment classifications. Part#1

General overview and discussion for machinery equipment in the oil and gas industry.

2-Pumps applications and technology.Part#2

-Pump Fundamentals.

– Pumps types and hydraulic coverage chart.

-Pumps applications and services.

3-API Centrifugal pumps design and applications. Part#3

-Pump Classifications.

-Pumps mechanical construction and material selection.

-Mechanical seal system.

-Lube oil system.

-Pumps skids installation.

4-Positive displacement pumps- Rotary type-Reciprocating type.Part#4

-Reciprocating pumps mechanical construction.

-Reciprocating pumps applications and services.

-Reciprocating pumps design and performance.

-Screw pumps mechanical construction.

-Screw pumps applications and services.

-Screw pumps design and performance.

5-Compressors applications and technology.Part#5

-Compressor Fundamentals.

-Compressor types and hydraulic coverage Map.

-Compressor applications and services.

6-Centrifugal compressors design and application.Part#6

-Compressor Nomenclature

-Definition and Historical Developments

-Application Map and Arrangements

-Compressor Models and Nomenclature

-Main Components.

-Rotor Dynamics and Materials.

-Thermodynamics Fundamentals.

-Non-dimensional Parameters

-Compressor Stage Design

-Multi-stage Performance

7-Reciprocating compressors design and application.Part#7

-Reciprocating compressor applications

-Gas Compression fundamentals

-Mechanics theory: forces and loads

-Component of reciprocating compressors

-Auxiliary Systems

-Main drivers

-Monitoring

8-Air compressor package/firewater pumps package.Part#8

9-Engines in OIl and Gas industry. part#9

Content