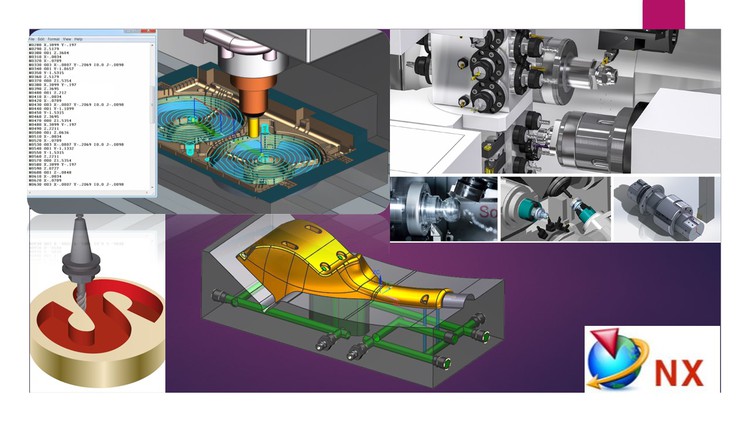

Manufacturing (CAM) & Customize G Code (Post Builder) & Injection Mold (Mold Wizard) – Solidcam 2023

What you will learn

After this course, you will be able to create G code for Milling, Turning and Wire EDM operations (3 Axis & Multi Axis).

You will be professional user in NX CAM.

You will learn the steps of NX Injection Mold (From start to the End)

You will be professional user in Solidcam.

Description

Course Main Contents (4Courses!):

- Course 1: NX CAM (Milling – Turning – Wire EDM)

- Course 2: NX Post Builder

- Course 3: NX Mold Wizard

- Course 4: Solidcam 2023

Cam Mold Package Contents:

NX CAM Milling (3Axis)

NX CAM Milling Multi Axis (4,5 Axis)

NX CAM Turning

NX CAM Drilling (3 Axis & Multi Axis)

NX CAM Wire EDM

NX CAM Millturn

Note➛ Make sure your 𝐔𝐝𝐞𝐦𝐲 cart has only this course you're going to enroll it now, Remove all other courses from the 𝐔𝐝𝐞𝐦𝐲 cart before Enrolling!

NX Post Builder (3 Axis & Multi Axis)

NX Injection Mold (From start to the End)

Solidcam Milling (3Axis, 4 & 5 Axis)

Solidcam Turning

Solidcam Millturn

Solidcam Drilling (3Axis, 4 & 5 Axis)

Description:

- You will be professional user in NX CAM.

- This Course covers conclusion of the most common operations that you will use during your actual work, the idea of this course to provide small course with low price contains the most important operations and options.

- NX CAM & Post Builder Course introduce the most common Milling, Turning and Wire EDM Operations ( 3 Axis & Multi Axis), the course will be step by step to make the full operations from beginning to generate the G code, also to customize the G code to be readable with any CNC machine type or any number of axis.

- After this course, you will be able to create G code for Milling, Turning and Wire EDM operations (3 Axis & Multi Axis).

Notes:

- You will download all parts that we used during the course and more parts for practice.

- You can send me any G & M codes to help you in post builder in your CNC machine.

- The implementation of this course is in NX 11 but you will be able to implement using any version.

- You will have full technical support.

- Weekly additional Exercise will be added to the course according to students requirements (If Required).

English

language

Content

Introduction

Introduction

NX CAM & Post Builder

CAM General Steps (3 Axis Rough & Finish Operations)

NX CAM & Post Builder Overview

Milling 3 Axis Operations (Roughing & Finishing)

3 Axis Rough Operations (Plunge Milling)

3 Axis Rough Operations (Corner Rough)

3 Axis Planar operation and Planar with IBW

3 Axis Face Milling operation and Face Milling Manual

3 Axis Finish Operations (Z Level Profile)

3 Axis Finish Operations (Z Level Corner Finish)

3 Axis Finish Operations (More Operations)

3 Axis Finish Operations (Another Example)

Milling Multi Axis Operations & Machine Simulation

Multi axis Finish Operations (Streamline operation)

Multi axis Finish Operations (Tool Axis Control-1)

Multi axis Finish Operations (Tool Axis Control-2)

Multi axis Finish Operations (Tool Axis Control-3)

Multi axis Finish Operations (Tool Axis Control-4)

Multi axis Finish Operations (Tool Axis Control-5)

Multi axis Finish Operations (Z Level 5 Axis Operation 1)

Multi axis Finish Operations (Z Level 5 Axis Operation 2)

Multi 4 axis Finish Operations (Streamline operation) with Machine Simulation

Drilling & Wire EDM Operations

Drilling Operations

Wire EDM Operation

Cutting Parameters & Non-Cutting Moves

Cutting Parameters & Non-Cutting Moves part 1-2

Cutting Parameters & Non-Cutting Moves part 2-2

Blank & Tool Creation and Cut levels option

Cut Levels

Cut Levels Ranges

Blank & Tool Creation

Turning Operations Basics

Turning Operations 1

Turning Operations 2

Post Builder Basics

Post Builder 3 Axis Milling

Post Builder Multi Axis Milling

Post Builder Fanuc Example

NX CAM Projects

Project 1 Milling 3 Axis

Project 2 Milling Multi Axis

Project 3 Turning Operations

Project 4 Drilling Operations

Project 5 Feature Based Machining

Project 6 General Milling & Drilling Operations

Project 7 – Multi Blade operations

Project 8 Milling Multi Axis with different Tool Axis positions

Project 9 Hole Milling & Thread Milling

Project 10 Groove Milling

Project 11 Millturn Operations

Project 12 Milling 3 Axis & Indexing

Solidcam 2023 (Manufacturing)

Solidcam Introduction

Solidcam General Steps (Roughing Operation)

Solidcam General Steps (Finishing Operation)

Solidcam 2.5D

Solidcam 2.5 Operations (Pocket, Face, Slot, Drilling, Profile)

Solidcam 3Axis Roughing

Solidcam 3Axis Roughing Operations 1

Solidcam 3Axis Roughing Operations 2

Solidcam Roughing Operation with Gauge Check

Solidcam 3Axis Finishing

Solidcam 3Axis Finishing Operations 1

Solidcam 3Axis Finishing Operations ( Linear Operation – Radial Machining )

Solidcam 3Axis Finishing Operations ( Offset Cutting – Spiral Machining )

Solidcam 3Axis Finishing Operations (Morphed Machining)

Solidcam 3Axis Finishing Operations (Boundary Machining)

Solidcam 3Axis Finishing Operations (3D constant stepover)

Solidcam Turbo 3D HSM

Solidcam 3Axis Finishing Operations (Rest Machining)

Solidcam Stock and Tool Creation

Solidcam Stock and Tool Creation

Solidcam Stock and Tool Creation and Finishing Operations

Solidcam Turning Basics

Solidcam Turning Operations

Solidcam Millturn Operations

Millturn Operations

Solidcam Multiaxis

Solidcam Multiaxis Finishing Operations (5 Axis Operation 1)

Solidcam Multiaxis Finishing Operations (5 Axis Operation 2)

Solidcam Multiaxis Finishing Operations (5 Axis Operation – Control tool axis)

Solidcam Multiaxis Roughing Operations

Solidcam Multiaxis Rotary Machining

Solidcam Multiaxis Multiblade Machining

Solidcam Rotary Machining

Solidcam Roughing – Finishing – Drilling Multiaxis

NX Mold Wizard Basics

Introduction and Injection Mold Overview

Initialize Project – CSYS Adjustments – Create Workpiece

Cavity Layout – Check Regions – Patch Surface

Define Regions – Create Parting Surface – Define Core and Cavity

Mold Base – Sprue Bushing – Locating Ring

Ejection System

Cooling System

Runner and Gate System

Runner Complete

Pocket and Run Simulation

Bill Of Material & Assembly Drawings

Mold Wizard Mini Examples

Mold Design Validation – Core and Cavity

Workpiece Edit Sketch

Patch Surface and Core & Cavity

Patch Surface

Parting Surface

Family Mold

Full Mold Example

Initialize Project to Ejection System

Cooling System to Run Simulation