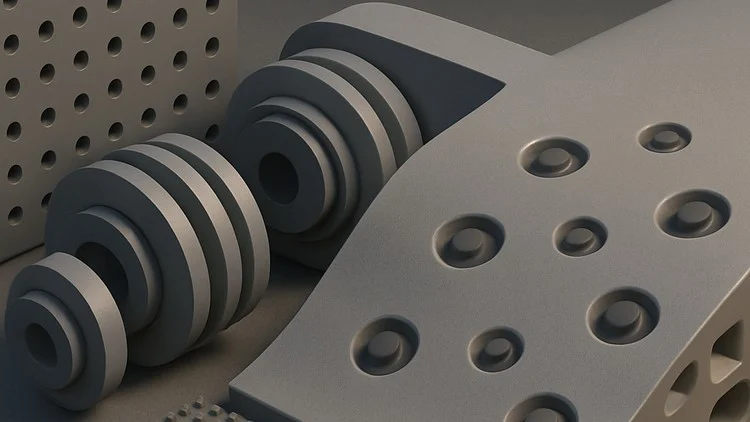

Acoustic Metamaterials for NVH Control

⏱️ Length: 2.0 total hours

⭐ 2.25/5 rating

👥 35 students

🔄 September 2025 update

Add-On Information:

Note➛ Make sure your 𝐔𝐝𝐞𝐦𝐲 cart has only this course you're going to enroll it now, Remove all other courses from the 𝐔𝐝𝐞𝐦𝐲 cart before Enrolling!

- Course Overview: Theoretical Foundations and Engineering Applications

- Analyze the paradigm shift from traditional acoustic treatments to engineered metamaterials that manipulate wave propagation through sub-wavelength structural geometry.

- Explore the fundamental physics of negative effective parameters, specifically focusing on how negative mass density and negative bulk modulus are achieved in periodic structures.

- Evaluate the distinction between Bragg scattering mechanisms and local resonance effects, determining which is more effective for specific NVH frequency ranges.

- Investigate the concept of acoustic bandgaps and how they are used to create “quiet zones” by completely prohibiting the transmission of certain sound frequencies.

- Examine the transition from theoretical physics to applied NVH engineering, focusing on how these materials address the limitations of the traditional Mass Law in low-frequency noise control.

- Understand the role of anisotropy in acoustic metamaterials and how it can be exploited to redirect sound energy away from sensitive cabin areas in vehicles or aircraft.

- Discuss the integration of active metamaterials and piezoelectric elements for adaptive NVH control that responds to varying operational conditions in real-time.

- Requirements / Prerequisites for Academic Success

- Possess a robust foundational knowledge of classical mechanics and the principles governing wave propagation in solid and fluid media.

- Demonstrate proficiency in engineering mathematics, specifically differential equations, complex variables, and linear algebra, which are essential for modeling wave equations.

- Have prior exposure to vibration theory and structural dynamics, including concepts such as natural frequencies, mode shapes, and damping ratios.

- Familiarity with standard NVH terminology, such as Decibels (dB), Sound Pressure Level (SPL), and Frequency Response Functions (FRF), is highly advantageous.

- Basic understanding of material science, particularly regarding the elastic properties of polymers and metals used in the fabrication of unit cells.

- Access to a computer capable of running simulation software for computational exercises involving structural-acoustic coupling.

- Skills Covered / Tools Used in Modern Acoustic Design

- Master the use of Finite Element Analysis (FEA) tools to model periodic structures and predict their acoustic performance before physical prototyping.

- Utilize Bloch-Wave Theory and periodic boundary conditions to calculate dispersion curves and identify frequency bandgaps within a lattice.

- Implement homogenization techniques to derive effective medium properties from complex, multi-phase microscopic geometries.

- Apply optimization algorithms to iteratively design unit cell topologies that meet specific weight and sound-absorption targets for industrial use.

- Gain proficiency in transfer matrix modeling (TMM) for analyzing the transmission loss and absorption coefficients of multilayered metamaterial panels.

- Learn to interpret impedance tube measurements and validate simulated metamaterial performance against empirical laboratory data.

- Explore 3D printing and additive manufacturing constraints as they relate to the high-precision fabrication of intricate metamaterial unit cells.

- Benefits / Outcomes for Career Advancement

- Develop the capability to design lightweight acoustic liners that provide superior noise attenuation without the significant mass penalties of traditional lead or heavy-layer plastics.

- Gain a competitive edge in the Electric Vehicle (EV) industry, where the absence of engine noise makes wind and tire noise more prominent and harder to treat.

- Learn to solve chronic low-frequency resonance issues in aerospace and industrial machinery that cannot be addressed by conventional foam or fiberglass.

- Acquire the specialized vocabulary and technical depth required to lead R&D projects in advanced materials and vibro-acoustics.

- Achieve the ability to propose multifunctional designs where the metamaterial serves as both a load-bearing structure and an acoustic filter simultaneously.

- Understand the commercialization landscape, including current patents and the scaling challenges of moving metamaterials from lab settings to mass production.

- Enhance your professional portfolio by mastering a frontier technology that is currently reshaping the future of noise, vibration, and harshness mitigation.

- PROS

- Focuses on cutting-edge solutions for low-frequency noise, which is the most difficult spectrum to control in modern engineering.

- Provides a perfect blend of rigorous physics and practical engineering application, ensuring concepts are grounded in reality.

- Offers insights into significant weight-saving strategies, which is a critical KPI for automotive and aerospace engineers today.

- Encourages innovation and creative thinking by moving beyond off-the-shelf materials to custom-engineered structural solutions.

- CONS

- The computational intensity required for modeling complex periodic structures may be demanding for students without access to high-performance workstations.

Learning Tracks: English,Design,Other Design

Found It Free? Share It Fast!