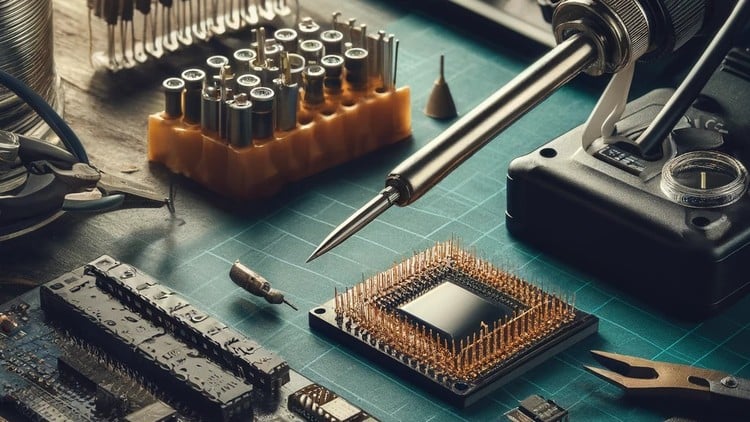

From Basics to Brilliance: Your Ultimate Guide to Soldering Mastery

⏱️ Length: 2.2 total hours

⭐ 3.71/5 rating

👥 12,420 students

🔄 February 2026 update

Add-On Information:

Note➛ Make sure your 𝐔𝐝𝐞𝐦𝐲 cart has only this course you're going to enroll it now, Remove all other courses from the 𝐔𝐝𝐞𝐦𝐲 cart before Enrolling!

- Course Overview

- The Philosophy of Precision Joining: This course represents a comprehensive transition from amateur assembly to industrial-grade craftsmanship. It moves beyond the simple act of melting metal, focusing instead on the “Pro Soldering Secrets” that define high-end electronics manufacturing. Students are guided through the subtle science of intermolecular bonding, ensuring that every connection made is not just electrically conductive, but structurally resilient enough to withstand years of mechanical stress and thermal cycling.

- A Curriculum Tailored for Modern Tech: Updated as of February 2026, the course content has been meticulously revised to reflect the latest shifts in the electronics industry. This includes a heavy emphasis on working with modern, lead-free solder alloys and high-density circuit board layouts that are common in today’s mobile devices and smart technology. The 2.2-hour runtime is densely packed with high-definition visual demonstrations that simulate a one-on-one apprenticeship experience, stripping away the fluff to focus on core mastery.

- From Theory to Practical Brilliance: The overview covers the essential physics of heat transfer, explaining why certain joints fail while others succeed. By understanding the “why” behind the “how,” learners develop a refined technical intuition. This allows them to troubleshoot difficult soldering scenarios, such as massive heat sinks or oxidized vintage components, with the same level of confidence they would apply to a standard through-hole resistor on a fresh PCB.

- Requirements / Prerequisites

- Minimal Entry Barriers: This course is designed to be accessible to everyone, requiring absolutely no prior experience with electronics or hand tools. Whether you are a dedicated hobbyist, a student, or a professional looking to sharpen your manual skills, the curriculum begins at the true ground level, assuming no previous technical background while rapidly scaling up to advanced professional secrets.

- Safety and Workspace Preparedness: A fundamental requirement for this course is a commitment to safety and an appropriate physical environment. You will need a workspace that allows for adequate ventilation or the use of a fume extractor to manage the off-gassing of flux. Additionally, basic safety gear such as impact-resistant eye protection is strongly recommended, as the course prioritizes professional-grade safety protocols that are often overlooked in casual DIY tutorials.

- Essential Hand-Eye Coordination: While the course provides all the knowledge, it does require a basic level of manual dexterity and patience. Soldering is a physical skill that improves with repetition, so learners should be prepared to spend time practicing the steady-hand techniques demonstrated in the lessons. The mental prerequisite is simply a desire for perfection and a willingness to follow a systematic, step-by-step approach to technical assembly.

- Skills Covered / Tools Used

- The Alchemy of Flux and Solder: You will dive deep into the chemical properties of flux, understanding how it removes oxidation at a molecular level to facilitate a perfect metallic bond. This section demystifies the various flux types, from rosin-based to water-soluble and no-clean variants, teaching you exactly which chemical agent is required for specific PCB finishes and component leads to ensure maximum wetting and minimal residue.

- Mastery of Thermal Management: One of the most critical skills covered is the precise control of heat. You will learn how to calibrate and use temperature-controlled soldering stations to prevent the two most common killers of electronics: cold solder joints and heat-damaged components. The course covers tip selection for various tasks, from fine-pitch SMD work to heavy-gauge wire tinning, ensuring the right amount of energy is delivered to the joint every time.

- Advanced Rework and Component Salvage: The course provides professional-level training on desoldering, an essential skill for any repair technician. You will master the use of copper desoldering wicks, spring-loaded vacuum pumps, and specialized low-melt alloys. These techniques allow you to remove multi-pin components and clean pads without lifting delicate copper traces or damaging the surrounding circuitry, a skill that separates the pros from the amateurs.

- Benefits / Outcomes

- Professional Grade DIY Repairs: Upon completion, you will possess the technical capability to repair expensive household gadgets, gaming consoles, and industrial equipment. This outcome provides a significant return on investment, as the ability to perform your own component-level repairs can save thousands of dollars in replacement costs over a lifetime, while also reducing electronic waste through sustainable maintenance.

- Confidence in High-Stakes Prototyping: For inventors and engineers, the primary benefit is the reliability of their prototypes. You will gain the peace of mind that comes from knowing your solder joints are factory-standard, eliminating the frustration of intermittent connections or project failures during critical testing phases. This course empowers you to build robust, professional-looking devices that are ready for real-world deployment.

- Career Readiness and Technical Literacy: For those seeking employment in the tech sector, these skills provide a tangible edge. Mastering the techniques shown in this course aligns your manual output with IPC-A-610 standards, the global benchmark for electronic assembly. This technical literacy makes you a more versatile asset in any laboratory, manufacturing, or repair environment, giving you a distinct advantage in a competitive job market.

- PROS

- Proven Pedagogy and Social Proof: With over 12,420 students and a consistent rating, the course utilizes a teaching method that has been successfully validated by a massive community of learners across various skill levels.

- Ultra-Efficient Learning Loop: The 2.2-hour duration is optimized for maximum information retention, providing a “straight-to-the-point” experience that respects your time while delivering all the necessary “secrets” for perfection.

- Future-Proofed Content: The February 2026 update ensures that the instructional materials reflect the current state of soldering technology, including the most recent advancements in tools, alloys, and board design.

- CONS

- Scope Limitation: Due to its focused duration, this course prioritizes manual soldering mastery and does not cover highly specialized industrial automation processes like wave soldering or high-volume pick-and-place oven profiling.

Learning Tracks: English,IT & Software,Hardware

Found It Free? Share It Fast!