MEMS Devices; Modeling, and Design Principles

⏱️ Length: 4.2 total hours

👥 309 students

🔄 January 2026 update

Add-On Information:

Note➛ Make sure your 𝐔𝐝𝐞𝐦𝐲 cart has only this course you're going to enroll it now, Remove all other courses from the 𝐔𝐝𝐞𝐦𝐲 cart before Enrolling!

- Course Overview

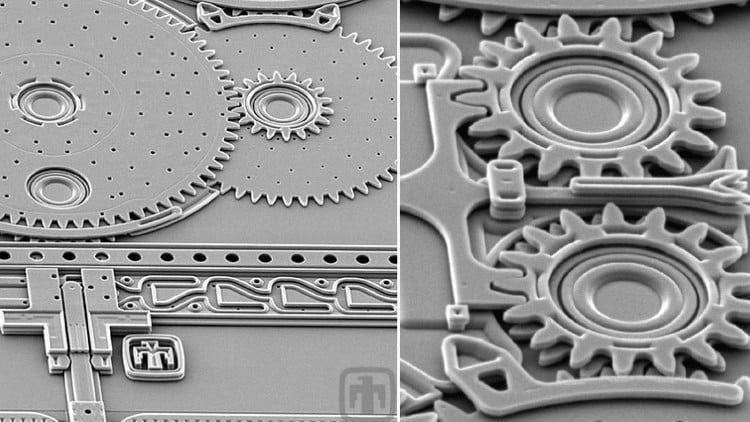

- This course, “Microelectromechanical Systems II: Design Principles,” is a crucial second installment in the MEMS curriculum, focusing on the systematic and strategic approach to designing functional micro-scale devices.

- Building upon foundational MEMS concepts, this course delves into the intricate process of translating theoretical understanding into practical, deployable micro-architectures.

- Students will explore the iterative nature of MEMS design, emphasizing the interplay between physics, materials science, and electrical engineering to achieve desired performance metrics.

- The curriculum is structured to provide a comprehensive understanding of the design lifecycle, from initial concept generation and feasibility studies to detailed modeling and optimization.

- Emphasis is placed on understanding the underlying physical phenomena that govern MEMS behavior and how these can be leveraged or mitigated through intelligent design choices.

- The course addresses the challenges inherent in micro-scale fabrication and how design considerations can significantly impact manufacturability and yield.

- Key themes include the selection of appropriate materials, the geometry optimization of micro-structures, and the integration of sensing and actuation mechanisms.

- Students will gain insights into common design methodologies and best practices employed in the MEMS industry.

- The objective is to equip learners with the knowledge and skills to design novel MEMS devices and to analyze and improve existing designs.

- This course serves as a bridge to more advanced MEMS topics and research, preparing students for real-world application and innovation in the field.

- Requirements / Prerequisites

- A solid grasp of fundamental physics principles, particularly mechanics (statics, dynamics, continuum mechanics) and electromagnetism.

- Prior exposure to or equivalent knowledge of introductory Microelectromechanical Systems (MEMS I) is highly recommended, covering basic device structures, fabrication processes, and transduction principles.

- Familiarity with basic semiconductor physics and device operation.

- Proficiency in a programming or scripting language (e.g., Python, MATLAB) for simulation and data analysis is beneficial.

- Basic understanding of material science concepts related to micro-fabrication (e.g., thin films, stress, etching).

- Exposure to differential equations and their application in modeling physical systems.

- Skills Covered / Tools Used

- Systematic Design Methodology: Developing a structured approach to designing MEMS devices, moving from requirements to detailed specifications.

- Physics-Based Modeling: Applying fundamental physical principles to create accurate models of MEMS behavior, including mechanical, thermal, electrical, and fluidic domains.

- Finite Element Analysis (FEA): Utilizing FEA tools to simulate and predict the performance of complex micro-structures under various operating conditions.

- Multi-Physics Coupling: Understanding and modeling the interaction between different physical domains within a MEMS device (e.g., electro-mechanical, thermo-mechanical).

- Optimization Techniques: Employing algorithms and strategies to optimize device geometry, material selection, and operating parameters for desired performance.

- Trade-off Analysis: Evaluating and balancing competing design considerations such as performance, power consumption, fabrication cost, and reliability.

- Design for Manufacturability (DFM): Incorporating fabrication constraints and considerations into the design process to ensure successful and cost-effective manufacturing.

- Sensor and Actuator Design Principles: In-depth study of design strategies for various MEMS sensing and actuation mechanisms (e.g., capacitive, piezoelectric, thermal).

- Simulation Software: Practical experience with industry-standard MEMS simulation tools (e.g., COMSOL Multiphysics, ANSYS, Lumerical, or similar platforms for modeling and simulation).

- Mathematical Modeling: Developing and solving mathematical equations that describe the behavior of MEMS components.

- Parameter Extraction: Techniques for extracting critical performance parameters from simulations and experimental data.

- Benefits / Outcomes

- Graduates will be capable of independently designing novel MEMS devices tailored for specific applications across various industries (e.g., healthcare, automotive, consumer electronics, aerospace).

- Acquire the ability to critically analyze existing MEMS designs, identify areas for improvement, and propose optimized solutions.

- Develop a strong intuition for the behavior of micro-scale systems, enabling effective troubleshooting and innovation.

- Become proficient in using advanced simulation tools to predict device performance, reducing the need for costly and time-consuming prototyping.

- Gain expertise in understanding and mitigating common MEMS design challenges such as stiction, residual stress, and parasitic effects.

- Enhance problem-solving skills by tackling complex multi-disciplinary design problems.

- Prepare for roles in MEMS research and development, product design, and advanced engineering positions.

- Foster a mindset geared towards innovation and pushing the boundaries of micro-scale technology.

- Understand the economic implications of design choices in MEMS, contributing to cost-effective product development.

- Build a solid foundation for pursuing advanced studies or research in specialized areas of MEMS.

- PROS

- Focuses on practical design application, moving beyond theory to actionable implementation.

- Covers essential simulation and modeling techniques widely used in the industry.

- Develops critical thinking and problem-solving skills applicable to real-world engineering challenges.

- Provides a comprehensive understanding of the entire MEMS design lifecycle.

- Enhances job prospects in a rapidly growing and technologically advanced field.

- CONS

- May require significant computational resources for advanced simulations.

Learning Tracks: English,Teaching & Academics,Engineering

Found It Free? Share It Fast!