Learn the advanced topic of forging. Design to Production and Production to Dispatch

What you will learn

what is metal forming, types of Metalforming, and how a forging industry work.

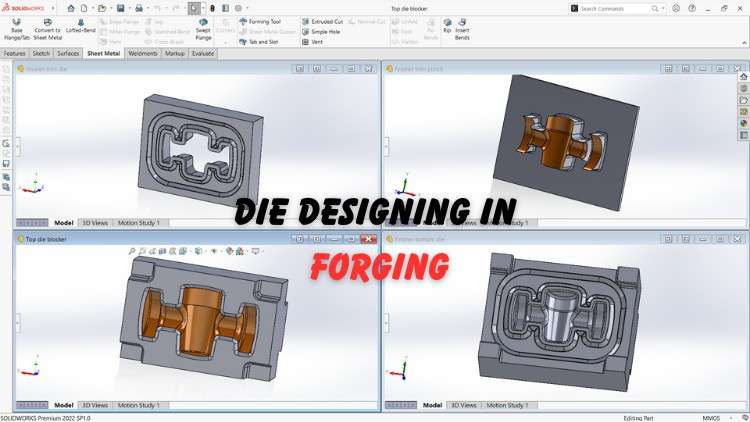

Designing of the die model and how simulation work.

Basic calculation which are done in an forging industry.

Design principles employed for designing forged parts.

How to make machining drawing to the forging model.

How to think like an forging expert.

Raw materials used in the forging process.

Description

Are you fascinated and eager to become a skilled metal forger? The “Metal Forming Process – Become a Forging Pro!” course is your gateway to the world of shaping metal into functional and decorative works of art. This comprehensive course will take you from a novice to a forging pro, providing you with the knowledge, skills, and hands-on experience needed to excel in the art of forging.

Course Highlights:

- Fundamentals of Forging: Explore the foundational concepts of hot and cold forging, understand the characteristics of various metal alloys, and learn the importance of safety in the forging process.

- Essential Tools and Equipment: Gain hands-on experience with the tools of the trade, including forges, anvils, hammers, tongs, and more. Learn how to select, use, and maintain these tools effectively.

- Heating and Temperature Control: Master the art of heating metal to the ideal forging temperature. Understand the specific temperature requirements for different materials.

- Basic Forging Techniques: Practice drawing out, upsetting, bending, twisting, and other essential forging techniques to shape metal with precision.

- Anvil Work and Hammer Control: Learn how to work with an anvil to create a variety of shapes and contours. Develop the finesse of hammer control to bring your creative ideas to life.

- Cooling, Tempering, and Finishing: Discover the crucial post-forging steps, including cooling and tempering processes, to ensure the durability and appearance of your creations.

- Hands-On Projects: Apply your newfound skills to a range of projects, from beginner-level items like hooks and tapers to more advanced creations such as knives, tools, and decorative pieces.

- Tools Maintenance: Learn how to maintain your forging tools, ensuring they remain in excellent working condition.

- Showcasing Your Work: Explore opportunities to share your forged creations with others, whether through social media, local markets, or craft fairs.

Join our “Metal Forming Process – Become a Forging Pro!” course and unlock your potential as a skilled metal forger. Whether you’re a beginner or have some forging experience, this course will provide the knowledge and practice necessary to take your skills to the next level. Craft, create, and forge a path towards becoming a forging pro.

Enroll today to embark on a journey of creativity, craftsmanship, and the timeless art of metal forging.

Content