Mastering the Art of Precision Metalworking: Techniques, Tools, and Theory

What you will learn

Gain a comprehensive understanding of the machining process and its applications in the metalworking industry.

Explore the various types of machines used in the machining process, and learn how to choose the right machine for a given task.

Discover the critical role of machining and part geometry in the machining process, including an in-depth look at rotational and non-rotational elements.

Perfect your drilling skills, including cutting conditions in drilling, and learn how to drill with precision and efficiency.

Master the art of turning, including cutting and turning conditions, and learn how to apply these techniques to produce precise and accurate cuts.

Enhance your drilling skills, including cutting and drilling conditions, and learn how to drill with precision and efficiency.

Get hands-on experience with the boring process, including horizontal and vertical boring techniques, and learn how to achieve efficient and accurate results.

Develop your milling skills, including cutting conditions in milling, and learn how to mill with precision and efficiency.

Perfect your drilling skills, including cutting conditions in drilling, and learn how to drill with precision and efficiency.

Description

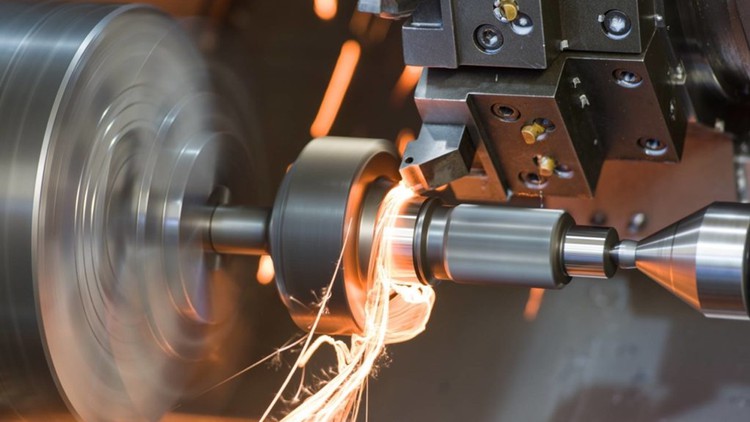

“Unlock Your Potential in Metal Machining with the Ultimate Comprehensive Course: ‘Fundamentals of Advanced Metal Machining Techniques'”

Are you looking to advance your metalworking skills and stay ahead of the competition in the industry? Then look no further, as this comprehensive and engaging course, “Fundamentals of Advanced Metal Machining Techniques,” is perfect for you. Led by a highly experienced instructor with a PhD degree in the field, this course provides a wealth of knowledge and hands-on experience in the art of metal machining.

The course covers a wide range of topics, from the introduction to machining processes, to the different types of machines used in the machining process, and the advantages and disadvantages of metal machining. You will learn about the crucial role that machining and part geometry play in the process, and explore cutting and turning conditions in turning, drilling, boring, and milling processes. You will also gain hands-on experience with each technique, allowing you to apply your knowledge in real-world scenarios.

By the end of this course, you will have a comprehensive understanding of the metal machining process and the skills you need to succeed in the field. This is a unique opportunity to take your metalworking skills to the next level and stand out in the highly competitive world of metalworking.

Don’t miss out on this incredible opportunity to invest in your future and become a master in metal machining. Enroll now and join the thousands of students who have already transformed their careers with this comprehensive course. Get ready to take your metal machining skills to new heights and unlock your full potential!

Content

-

Course Overview

- Delve into the foundational scientific and engineering principles that govern efficient material removal in metal machining.

- Understand the intricate relationship between workpiece materials, cutting tools, and machine kinematics to achieve desired outcomes.

- Explore the diverse landscape of conventional machining operations, emphasizing process selection logic for various component geometries and functional requirements.

- Grasp the significance of machine tool structure, rigidity, and power in influencing machining performance and part quality.

- Cultivate a robust understanding of shop floor safety protocols, personal protective equipment, and hazard identification crucial for any metalworking environment.

- Examine the impact of chip formation, heat generation, and tool wear on machining efficiency, surface integrity, and overall component lifespan.

-

Requirements / Prerequisites

- A strong interest in mechanical fabrication, hands-on problem-solving, and precision manufacturing processes.

- Basic mathematical literacy, including foundational geometry and arithmetic, for interpreting dimensions and calculating machining parameters.

- Ability to comprehend and follow technical instructions and safety guidelines meticulously.

- No prior direct machining experience is required; this course is designed as a comprehensive entry point for aspiring machinists and engineers.

- Commitment to diligent practice and adherence to all workshop safety procedures.

-

Skills Covered / Tools Used

- Metrology and Inspection: Proficiency in using precision measuring instruments such as calipers, micrometers, and dial indicators for accurate dimensional verification.

- Workholding and Fixturing: Mastering techniques for securely clamping and indexing workpieces on various machine tools to ensure stability and accuracy during machining.

- Cutting Tool Selection & Management: Knowledge of different cutting tool materials, coatings, geometries, and their appropriate application for diverse materials and operations, including recognizing and addressing tool wear.

- Manual Machine Setup: Developing the practical skills for aligning, leveling, and calibrating conventional manual lathes, milling machines, and drill presses.

- Surface Finish Optimization: Applying techniques and selecting appropriate cutting conditions to achieve specified surface roughness and aesthetic quality for machined parts.

- Troubleshooting Common Machining Issues: Diagnosing and rectifying common problems encountered in machining, such as chatter, excessive tool wear, poor chip evacuation, or dimensional inaccuracies.

- Reading and Interpreting Shop Drawings: Translating engineering blueprints, including GD&T (Geometric Dimensioning and Tolerancing) symbols, into practical machining operations.

- Primary Machine Tools: Hands-on operation of traditional manual lathes, vertical and horizontal milling machines, drill presses, and various sawing equipment.

-

Benefits / Outcomes

- Foundational Expertise: Establish a robust understanding of metal machining that serves as an essential stepping stone for advanced manufacturing technologies and further specialization.

- Enhanced Problem-Solving: Develop critical thinking and analytical skills to approach complex fabrication challenges, material selection, and process optimization.

- Career Pathway: Prepare for entry-level roles, apprenticeships, or further education in machine shops, manufacturing engineering, product development, or industrial maintenance.

- Safety Competency: Operate conventional machinery responsibly and safely, minimizing risks to self and others in a professional workshop environment.

- Quality Assurance Mindset: Cultivate an acute eye for precision, accuracy, and adherence to specifications, ensuring the production of high-quality components.

- Independent Fabrication: Gain the confidence and practical ability to plan and execute small-scale machining projects from concept to finished part.

-

PROS

- Provides essential, hands-on practical skills highly valued across diverse manufacturing industries.

- Fosters a deep appreciation for precision craftsmanship and material science interactions.

- Develops critical thinking for process planning, material selection, and problem resolution.

- Strong emphasis on safety protocols and best practices in a workshop setting.

- Serves as an excellent foundational course for understanding and transitioning to advanced CNC machining and automation.

-

CONS

- Mastering the practical skills requires significant dedication and hands-on practice, which can be time-intensive.