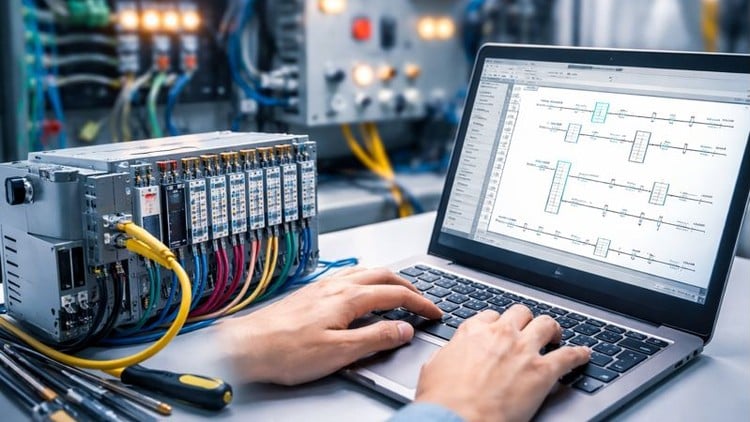

Learn Ladder Logic, Structured Text, and Function Blocks. Master conveyor control, I/O configuration, and real-world

⏱️ Length: 10.1 total hours

👥 187 students

Add-On Information:

Note➛ Make sure your 𝐔𝐝𝐞𝐦𝐲 cart has only this course you're going to enroll it now, Remove all other courses from the 𝐔𝐝𝐞𝐦𝐲 cart before Enrolling!

-

Course Overview

- Embark on a transformative journey into industrial automation, mastering Siemens PLC programming from basic foundational concepts to advanced techniques.

- Designed for aspiring automation engineers, electricians, maintenance technicians, and control system professionals eager to command the industry-leading Siemens TIA Portal platform.

- Unlock TIA Portal’s full potential for effectively designing, implementing, and troubleshooting sophisticated industrial control systems with efficiency and precision.

- Gain a holistic understanding of the Siemens automation ecosystem, proficiently bridging theoretical knowledge with practical, real-world application scenarios.

- Prepare effectively for complex industrial challenges by building a robust and highly relevant skill set on the universally recognized Siemens automation framework.

- Explore the systematic approach of project planning, structured development, and efficient deployment strategies within the comprehensive TIA Portal engineering environment.

- Understand the critical and evolving role of Programmable Logic Controllers (PLCs) in modern manufacturing, advanced process control, and intelligent factory solutions.

- Acquire proven methodologies for optimizing diverse industrial processes through the development of reliable, high-performance, and scalable PLC programming.

-

Requirements / Prerequisites

- Familiarity with basic electrical principles, digital logic concepts (e.g., AND, OR, NOT gates), and fundamental control circuitry.

- A foundational understanding of computer operation, file management, and navigating Windows-based software environments.

- Access to a personal computer capable of running Siemens TIA Portal software (ideally V16 or newer is strongly recommended for optimal experience).

- Prior exposure to any programming language or scripting concepts is advantageous but not a strict prerequisite for this comprehensive course.

- A strong desire to engage with industrial automation, learn advanced control techniques, and develop logical problem-solving capabilities.

- Basic conceptual awareness of common industrial sensors, actuators, and their functional roles within automated systems.

- Commitment to actively participate in practical exercises, engage with simulated scenarios, and apply learned concepts to reinforce understanding.

-

Skills Covered / Tools Used

- Skills:

- Mastering the TIA Portal integrated engineering framework, including efficient project navigation, hardware catalog management, and user interface customization.

- Proficiency in creating, organizing, and accessing data blocks (DBs) for structured data storage and efficient program organization within PLC projects.

- Implementing complex arithmetic, comparative, and data manipulation instructions for various process calculations, scaling, and data transformations.

- Developing robust error handling routines, advanced fault detection mechanisms, and intelligent alarm generation within PLC code for enhanced system reliability.

- Skill in utilizing TIA Portal’s advanced simulation capabilities (e.g., PLCSIM Advanced) for thorough program testing, debugging, and virtual commissioning.

- Designing basic Human Machine Interface (HMI) integration strategies for intuitive operator interaction, data visualization, and process control.

- Expertise in employing symbolic addressing, comprehensive commenting, and cross-referencing features for creating highly readable and maintainable PLC projects.

- Applying program modularization strategies and sub-routine development using Functions (FCs) and Function Blocks (FBs) to manage large-scale automation projects efficiently.

- Leveraging advanced diagnostic techniques within TIA Portal, including online monitoring, forcing variables, trend analysis, and utilizing diagnostic buffers.

- Tools Used:

- Siemens TIA Portal (Totally Integrated Automation Portal) engineering software suite.

- Siemens PLCSIM Advanced for comprehensive offline and online program simulation.

- Integrated documentation and reporting features available within TIA Portal for project traceability.

- Skills:

-

Benefits / Outcomes

- Empowerment to confidently design, implement, and commission sophisticated industrial automation solutions from initial concept to operational deployment.

- Significantly enhanced career prospects in automation engineering, control systems integration, industrial maintenance, and related technical roles.

- Developed confidence in rapidly troubleshooting complex PLC programs and efficiently diagnosing operational issues in live production environments.

- Ability to strategically contribute to smart manufacturing initiatives and actively participate in the evolving landscape of Industry 4.0 paradigms.

- A robust foundational knowledge for pursuing advanced Siemens certifications or specializing in niche industrial automation domains.

- Mastery of industry best practices for developing highly robust, scalable, and maintainable PLC programming solutions that adhere to professional standards.

- Increased problem-solving acumen applicable across diverse industrial sectors, from discrete manufacturing to complex process control scenarios.

- The capability to optimize production processes, minimize costly downtime, and significantly improve overall operational efficiency through intelligent control.

- A strong understanding of safety-critical programming principles to design compliant, secure, and reliable automation systems.

-

PROS

- Comprehensive Skill Set: Covers foundational to advanced topics, ensuring a well-rounded and deeply practical understanding of Siemens PLC programming.

- Industry Relevance: Focuses on TIA Portal, a leading and widely adopted platform, making acquired skills directly applicable to countless industrial jobs globally.

- Hands-On Learning: Emphasizes practical application and real-world scenarios, making complex concepts tangible and directly usable in professional settings.

- Career Advancement: Equips learners with highly sought-after expertise, opening doors to new career opportunities or significant professional growth within their existing roles.

- Expertise Building: Facilitates a deep understanding of efficient program design, advanced diagnostics, and robust system integration techniques.

- Future-Proofing: Provides a strong base for understanding and adapting to evolving automation technologies and industry trends.

-

CONS

- Software Cost & Access: Full Siemens TIA Portal software licensing can be a significant investment, potentially limiting accessibility for individuals without institutional support or trial versions.

- Hardware Abstraction: While strong on simulation, dedicated hands-on experience with physical Siemens PLC hardware is often crucial for complete mastery and may require additional investment.

Learning Tracks: English,IT & Software,Hardware

Found It Free? Share It Fast!