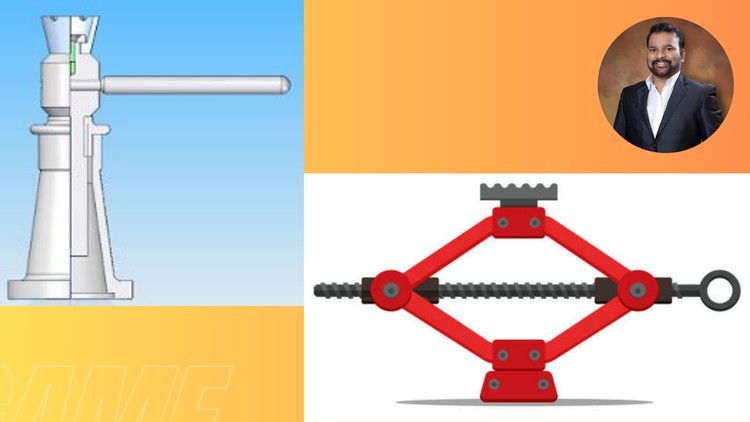

Design of Power Screw for Various Applications

What you will learn

DESIGN AND ANALYZE the cotter and knuckle Joints, levers and components subjected to eccentric loading.

DESIGN shafts, keys and couplings under static loading conditions.

ANALYZE different stresses in power screws and APPLY those in the procedure to design screw jack.

ANALYZE different stresses in power screws and APPLY those in the procedure to design screw jack.

EVALUATE & INTERPRET the stress developed on the different type of welded and threaded joints.

APPLY the design and development procedure for different types of springs.

Why take this course?

Welcome to the Advanced Power Screw Design and Analysis course, a deep dive into the mechanics and design principles of power screws. This course provides a thorough exploration of the terminology, analysis, and practical design of power screws, essential for engineering applications in various mechanical systems.

Note➛ Make sure your 𝐔𝐝𝐞𝐦𝐲 cart has only this course you're going to enroll it now, Remove all other courses from the 𝐔𝐝𝐞𝐦𝐲 cart before Enrolling!

Course Content:

- Terminology of Power Screws: Begin with a foundational understanding of the key terms and concepts related to power screws. This will set the stage for more advanced topics.

- Torque Analysis: Learn the principles of torque analysis, focusing on how torque is transmitted through power screws and the factors influencing performance.

- Design of Power Screws: Explore the design considerations for power screws with square and trapezoidal threads. Understand the design criteria and calculations required to create effective and reliable power screws.

- Collar Friction Torque: Study the impact of collar friction on screw performance, including methods for calculating and mitigating frictional losses.

- Self-Locking Screws: Examine the mechanics and design of self-locking screws, including their efficiency and applications in preventing unwanted movement.

- Efficiency of Screws: Assess the efficiency of square threaded and self-locking screws. Learn how to evaluate and improve screw efficiency to enhance system performance.

- Design of Screw, Nuts, and C-Clamps: Apply design principles to create and optimize screws, nuts, and C-Clamps, focusing on practical and functional aspects.

- Design of Screw Jacks: Investigate the design and application of screw jacks, including their operation, efficiency, and design considerations.

- Differential and Compound Screws: Explore the complexities of differential and compound screw mechanisms, understanding their unique design features and uses.

- Re-circulating Ball Screws: Delve into the design and operation of re-circulating ball screws, a key technology for high-precision and high-efficiency mechanical systems.

English

language

Found It Free? Share It Fast!